Many methods to achieve this goal, such as the Fishbone Diagram, investigate the relationship between the effect of the problem and its possible causes. When it comes to problems, both designers and managers can fail to find the solution, and part of this failurĮ is their inability to find the correct causes of problems. Root Cause Analysis Handbook: A Guide to Efficient and Effective Incident Investigation Solve It!: The Mindset and Tools of Smart Problem Solvers

#FISHBONE DIAGRAM CAUSE AND EFFECT HOW TO#

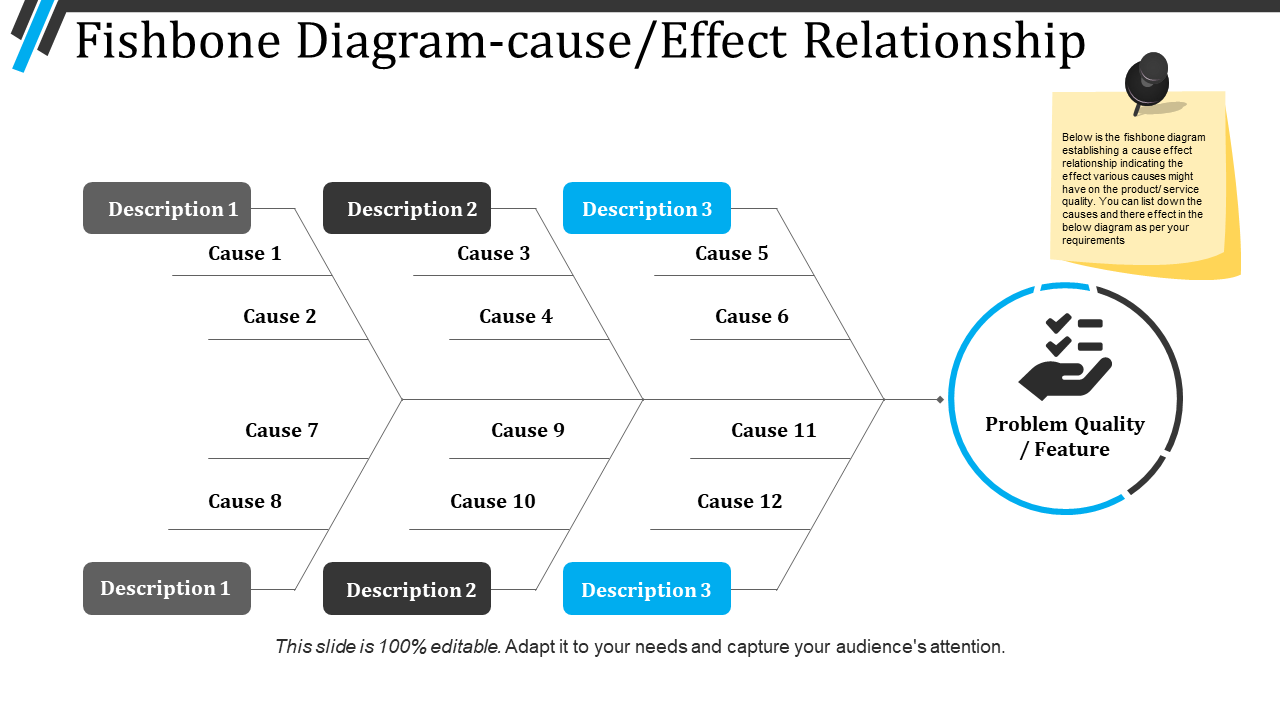

Example of how to apply the Ishikawa Diagram in identifying the root-causes of problems. The below video provides another example of how to use the Fishbone Diagram in identifying the root causes of problems. Understanding the different causes may include using research methods such as interviews, focus groups, and surveys. Once the diagram is complete, and causes are organized in the model, the next step is to investigate and discuss each possible cause and rank them based on their priority and influence on the problem. Cause effect diagram step 3 Step 4: Analyse the findings For example, under Man Power, causes can be a lack of motivation, lack of skills, under-evaluated skills, hiring inappropriate skills, or fixed working hours. Step 3: Investigate possible causes of the problemĪfter drawing the main general categories, where we can add causes, the discussion starts to investigate all the possible causes for the problem and organize them under the five categories. In this example, we’ll use the manufacturing industry model (5 Ms): Machine, Method, Material, Man Power, and Measurement. You can use any of the above highlighted three cause models. Then, define the main categories of factors that can lead to the root causes of the problem. The Fishbone Diagram showing the problem (effect) Step 2: Define the main causes model In the Design Studio example, we start by writing the Effect (Lack of Creativity) or the problem on the right side, as shown in the figure below. Therefore, the problem should be clearly addressed to investigate the related causes.

The effect, or problem, results from one or multiple causes. To understand how the Cause-Effect Diagram works, we will explore an example of a problem and see how to use the Fishbone Diagram to investigate a problem, which is why a design studio company always fails to reach an innovative product or service. While this diagram looks similar to other creative thinking methods, such as mind maps and starbursting, it focuses on solving problems rather than exploring ideas. Then, the possible causes of the problem are explored by creating branches from the line that link between cause and effect sections, as we will explore in the following example. The diagram starts with two main sections Cause on the left and Effect on the right (video 1). The name Fishbone Diagram comes from the final shape of the diagram after analysing the problem because the structure looks like a fishbone, which is built gradually from right to left during the problem-solving session.

– Service industry (5 Ss) : Surrounding, Suppliers, Systems, Skills, and Safety – Marketing industry (7 Ps) : Product, Price, Place, Promotion, People, Process, and Physical Evidence – Manufacturing industry (5 Ms) : Machine, Method, Material, Man Power, and Measurement The categorisation of the cause of a problem varies based on the industry, such as the following: The Cause and Effect Diagram can be implemented during the development brainstorming session to discover the roots of a specific problem or identify the bottleneck in a particular process by categorising the causes of problems into six main types: people, methods, machines, materials, measurements, and environment. The diagram is also known as the Ishikawa Diagram, Cause and Effect Diagram, and Herringbone Diagram. The term, Fishbone Diagram, was first coined by professor Kaoru Ishikawa in his book “Introduction to Quality Control,” published in 1990. Based on the results, the team can build an effective solution to eliminating the problem. The Fishbone diagram (also known as the root-cause analysis and Ishikawa diagram) is used to identify the root causes of problems by identifying the different factors that may cause the problem. Step 3: Investigate possible causes of the problem.

0 kommentar(er)

0 kommentar(er)